Buildings that twist, bend and scream perfection

OMG! How does one build like this...

The pictures above show the twisted, bent and warped facades of the stainless steel clad Frank Gehry's Beekman Towers, Frank Gehry's IAC Headquarters, Jean Nouvel's 100 11th Ave, and Thom Mayne's new Academic Building at Cooper Union, all in New York.

The question I ask is not how one thinks of these buildings, dreams them up at night or during a drunken creative breakthrough. The key question for me is how does one take these magnificent forms from paper to reality. Maybe I am jaded. But the quest to understand design to execution has dictated my professional journey, where I started as an architect who believed that design was supreme and then went on to studying and practicing as a city planner and real estate professional in an attempt to unravel the processes that translate design dreams to reality. I still think that design is supreme but really it can be so much more if implemented correctly on budget and on time. My architect friends may hate me for saying this but in a way I am their biggest proponent. I think that architects are supremely talented, way ahead of the times, and therefore I believe that their creations need to be built so the world can be a better place.

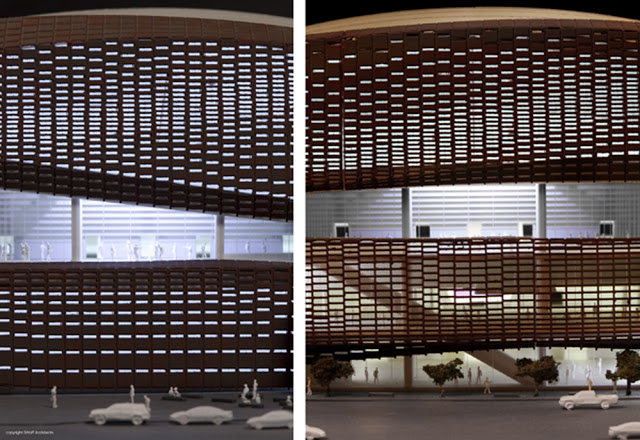

Renderings showing the proposed Barclays Center in Brooklyn, New York

So going back to the question of 'How does one build like this?'. The above rendering shows the new Barclays Center under construction in Brooklyn, New York. The project is being built by developer Forest City Ratner as part of the very controversial Atlantic Yards project in Brooklyn, New York. Interestingly, I had the opportunity to work with their parent company Forest City Enterprises in 2008-09 on mill redevelopment projects as part of the development team. Forest City Ratner is also the developer for the stately Beekman Towers (image on top).

Detail of the facade at Barclays Center made with pre-weathered metal lattice

Last week, I attended a talk by Jonathan Mallie from SHoP Architects and Construction who are the architects on the job and are facilitating the construction.

The building's external form is designed with concentric helical bands that are superimposed on each other. To mask this snaking form, the building will be skinned with a weathering steel latticework system. The lattice system goes over a glass curtain wall. Before installation, the metal lattice panels are pre-weathered to obtain a patina that makes them look older (weathered) in a design attempt to resemble the historic brownstones of Brooklyn.

And here is the kicker in the whole story, the proposed skin is comprised of 12,000 uniquely designed mega panels; each unique in size, shape, and individual pattern of folds and bends. Yes, I know....CRAZY ! Imagine implementing something like this. Imagine manufacturing each panel individually, imagine producing 12,000 individual drawings for each panel and then imagine coordinating the whole process, managing delivery and installation....

Photo of the lattice panels being installed on-site at Barclays Center

How does one go about a challenge like this? In this case, SHoP Architects have a sister company called SHoP Construction who played the key role of coordinating all design and construction efforts. They employed technology and created a Catia based 3-dimensional model that integrated all the building components with a back end database that recorded the details of each component (so size, individual design and special characteristics). As an example of attention to detail, SHoP actually analyzed the optimum size of panels and optimum stacking for road transportation (panels are being manufactured in Indianapolis and the project is in New York, 700 miles away from each other). After this exercise, they actually modified the design of the lattice panels to ensure efficient transportation. This is also an example of how an entity like ShoP Construction was critical to project implementation that allowed for communication between designers, manufacturers and contractors, who in spite of being in the same industry generally speak different languages, meaning have very different roles, scope of work and motivations.

The centralized model and database was also used to generate the 12,000 unique drawings for individual panels. And then they did another cool thing, implemented another idea that has probably never been done before.. Each panel was assigned and identified by a bar code. So each drawing had a bar code that was repeated to tag the panel once manufactured, was scanned when the panel was put on the truck to be transported to site, again scanned when it reached site and then again once it was installed. Taking it all the way, this electronic information was then made available real-time through a project website that kept all team members from the owner, architect, manufacturer, contractor up to date on where each of the 12,000 panels were at any given point in time. All this is so cool, that I just can't type fast enough to tell you all about it... just thinking about it makes me jittery with excitement...Oh and of course, the electronic tracking system was also available to the project team as an IPhone application...

Learning about these wonderful stimulating innovations in design and implementation left me wanting more...The mantra to successful project implementation is seamless communication between all parties. With technology this communication can improve by leaps and bounds. For our project, we rely on digital photographs, skype calls and in-person meetings with all project leaders. It works well for now, but I will end the post hoping that in the future we will endevour to design and build more complex buildings and embrace cutting edge technology to do the same.

Read more about,

The weathering process for lattice panels

at Barclays Center

Video of construction sequencing at Barclays Center

Read New York Times architectural review of,

Frank Gehry's IAC Headquarters

Jean Nouvel's 100 11th Ave